Start-up Sunfire’s e-fuels can decarbonise industries most addicted to fossil fuels

Company profile

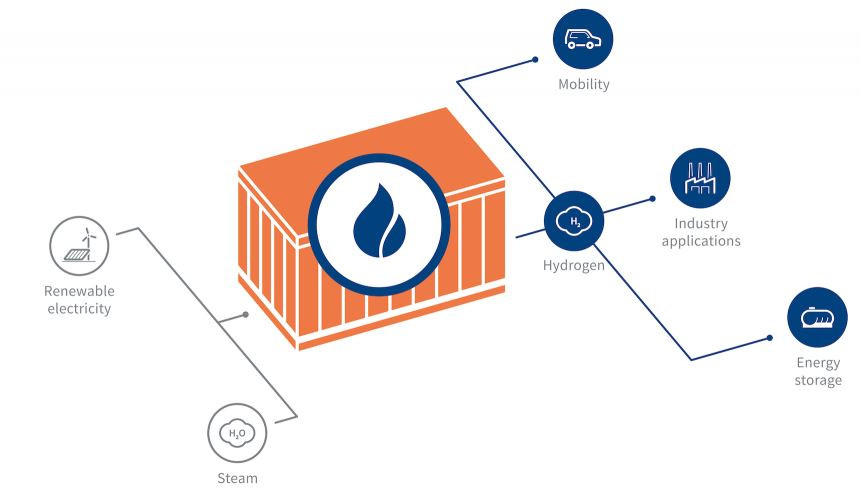

- Power-to-gas and power-to liquid specialist Sunfire develops and manufactures systems for the production of renewable industrial gases and fuels – also known as e-gases, e-fuels or e-chemicals – that can substitute mineral oil and natural gas. It uses renewable electricity to produce so-called green hydrogen, which can either be used directly or transformed in further processes into CO2-neutral e-gasoline, e-diesel or e-kerosene.

- Sunfire’s steam electrolysers use waste heat from industrial processes to make the conversion of electrical into chemical energy more efficient than in conventional electrolysers. German steelmaker Salzgitter and Sunfire will build the world’s largest High-Temperature Electrolyser to make green hydrogen for use in steelmaking.

- Sunfire started off with private investors and involvement from the oil industry (Total Energy Ventures) and the utility sector (Electricite de France and Inven Capital, the venture capital arm of Czech energy provider CEZ). In early 2019, the company secured 25 million euros in venture capital when Luxembourg-based technology company Paul Wurth, a subsidiary of metals industry equipment maker SMS, became the new lead investor. Sunfire says the investor will provide access to the global metals industry, which is increasingly using renewable hydrogen.

- Sunfire took over German Fuel Cell specialist New Enerday in late 2018

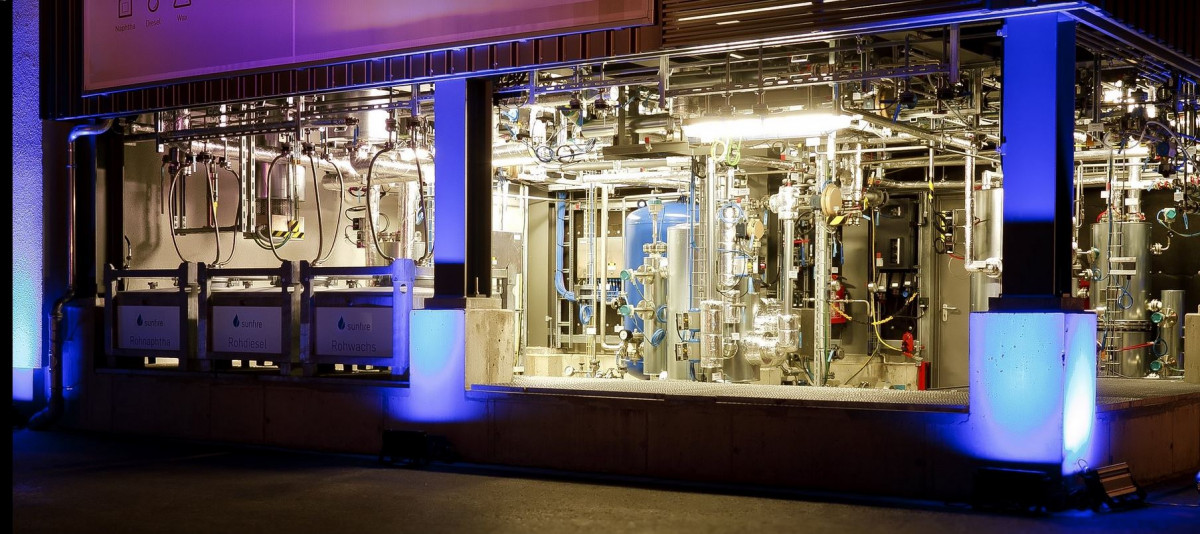

- Sunfire says it wants to implement commercial multi-megawatt projects starting this year.

- Rotterdam The Hague Airport is developing plans to produce renewable jet fuel in a pilot project, using CO2 captured from ambient air by Swiss start-up Climeworks and electrolyser cells developed by Sunfire. “This would be the first time ever that renewable jet fuel from air production exceeds laboratory scale of a few litres per day,” Sunfire states.

- Austrian utility VERBUND is building a pilot plant to store renewable electricity by making green hydrogen and then partially substituting natural gas in the country’s largest power plant.

- Sunfire has been repeatedly included in the Global Cleantech 100 list.

Can Salzgitter cut Germany's CO2 emissions with low-carbon steel project?

Hydrogen start-up Sunfire reports rising demand from cosmetics industry

Ten German startups in Cleantech Group’s global 100 cleantech list

Why Sunfire matters

- Power-to-gas and power-to-liquid technologies are considered essential for the decarbonisation of sectors where the direct use of electricity is difficult or impossible, such as heavy goods transport, aviation, steelmaking, or chemicals. Therefore, the technology is key to powering these sectors with renewable energy - a transformation sometimes referred to as "sector coupling". An added bonus: E-fuels and green hydrogen can be used in existing transport and storage infrastructure, and burned in conventional engines - for example in trucks, ships, and planes.

- The technology has reached a critical stage as it starts to move from pilot projects to the first industrial-scale applications. The drawback: Making e-fuels remains comparatively expensive, because it requires large amounts of renewable electricity.

- The production of renewable fuels can be combined with carbon capture and usage (CCU) technologies, or with direct CO2 removal from ambient air.

- Sunfire also illustrates how comparatively small start-ups can be instrumental for decarbonising traditional industry giants.

Find CLEW coverage of Sunfire here.

Sector coupling - Shaping an integrated renewable energy system

Power-to-gas: Fix for all problems or simply too expensive?

Industry bets on gas as last trump card in Energiewende

What Sunfire says

Clean Energy Wire spoke to co-founder and CEO Carl Berninghausen.

Clean Energy Wire: How would you evaluate the current progress of Germany’s energy transition?

Berninghausen: I believe a number of structural issues remain unsolved and that many politicians both in Germany and Europe do not act as decisively as they should because they must overcome several quandaries at once. On the one hand, we have vested interests resulting from Germany’s system of renewable feed-in tariffs. The support payments were justified to begin with and have helped us enormously to get started, but many players have become dependent on the payments and are now starting to scream terribly loud whenever someone calls for a reform, which has become necessary if we really want to become renewable on a large scale.

Secondly, we need to overhaul our system of how we design and finance our electricity grids. At present, policymakers want as many payers as possible, but end up reaching into the pockets of those who are working hard to improve the grid situation. For example, policy wants to ensure that power grids remain stable in the future. We still have adjustable power generation at our disposal, but we won’t have that option in a renewable future. This creates instability – especially if we keep on adding renewables to the system – and therefore we need to add large adjustable consumers that can pay for the additional renewable generation capacities, and add the necessary flexibility at the same time. In other words: We simply shift the flexibility necessary for a stable electricity system from the generation to the consumption side.

Power-to-gas and power-to-liquid installations can be throttled down very quickly for a few hours whenever this is necessary to stabilise the system. This should be rewarded, not penalised by high grid fees. We need to overcome these contradictions if we want to make headway in Germany.

The use of hydrogen to decarbonise the economy has become a hot topic recently. What’s your perception of the development? Has the market started moving?

The subject has certainly come into vogue politically. This trend offers advantages because we see hydrogen as one of the solutions to become renewable. We need a combination of different energy sources, and link them up intelligently - hydrogen is not necessarily renewable, and renewables don’t necessarily need batteries.

Hydrogen is a molecule that is difficult to tame: It’s difficult to store, transport is complicated and it presents a high ignition hazard. But at the same time, it’s present everywhere in our daily life – not in its pure form, but in combination with other elements, mostly carbon. Our bodies and our food are made up of hydrocarbons, and the same is true for plastics, fuels, gases and so on.

Wherever hydrogen can be used in its pure form without too many problems, the renewable variety should be used. But we have to think beyond that and also replace all the hydrogen hidden in all these other products with green hydrogen made with renewables. If you approach the subject from this direction, it’s much easier to reconcile the vision of a renewable future with our existing world. Hydrocarbons can be used in existing propulsion systems, and distributed in existing logistics infrastructure – it’s all there already.

Could you explain how Sunfire stands out from your competition? What’s your unique selling point?

Electrolysis converts electric energy into chemical energy. This chemical energy can either be stored in hydrogen, carbon monoxide or hydrocarbons. Our approach differs from other electrolysis specialists because firstly, we work with different materials, and also at temperatures that are significantly higher. We use so-called solid oxide technology, which is much more efficient – we need less electricity to produce a certain amount of chemical energy. With a given amount of renewable power, we can make around 25 percent more products.

Secondly, our form of electrolysis cannot only split water to use the hydrogen contained in it, but it can also split carbon dioxide. That’s because in conventional electrolysis, water molecules are broken down because the hydrogen is pulled out. In our system, the oxygen is pulled out. Therefore, if you want to break down carbon dioxide to activate the carbon later, you have to use our electrolysis, because it cannot only generate hydrogen, but also hydrocarbons – the basic ingredient for our entire petro-chemical industry. Many pure hydrogen applications will remain niche products for some time to come, which is why we focus on other uses as well.

Are you thinking of using hydrogen in aeroplanes, for example?

Yes, exactly. Today, a conventional refinery only uses crude oil and natural gas. In the future, it could also use our hydrocarbons. If we have enough product, refineries could run 100 percent renewable without any changes to their output. The supply from the refinery will remain what we’re used to – it will be slightly cleaner and burn more cleanly, but it will be essentially the same product. Therefore, it will be much easier to market this renewable energy compared to other approaches that require changes to existing distribution infrastructure and entirely new propulsion systems.

What do you consider the most important milestones for your company in the future?

In the coming three to five years, we want to get two large commercial projects on track. Our new lead investor, SMS Group, the world’s largest technology provider for the steel and iron sector, wants to make steelmaking clean by using our technology. Today, the steel industry accounts for six percent of global emissions – apart from cement, it’s the worst industrial polluter in this regard. Therefore, it offers an incredible playing field for us. SMS wants to devise a steelwork without a coking plant, meaning coal would no longer be used to refine the steel. In a first step, coal is replaced with methane, which afterwards is increasingly substituted by electrolysis gas.

This approach could also be used by steelmaker Salzgitter, which already uses one of our electrolysers and is currently building a second one.

If this steel project comes to fruition, it would constitute a paradigm shift in the steel industry. If we can demonstrate that it works on a large scale, it will result in political pressure to really start the conversion. In cooperation with SMS, we want to be the first ones to present a clean steel mill to the world. Perhaps in Salzgitter, which would be nice, because the company has accompanied us from the first step. But other steelworks are also interested.

Secondly, we want to realise a large-scale project to produce renewable fuel in order to offer refineries an alternative to crude oil. This will require large amounts of renewable electricity, which is why we would like to realise it in Germany with support from the relevant ministries – that would be our dream scenario. Alternatively, we are preparing a project in Norway because the country is ideal for several reasons. It only has renewable electricity in its grid, and it still has huge potential to roll out wind power. Secondly, Norway is politically and mentally geared towards renewable energy. Thirdly, the country is used to being Europe’s energy provider – they already have the knowledge, engineers, refineries, infrastructure and so on. Additionally, they invested the money earned with crude oil very wisely and the country is now prepared to use it to transform itself into the renewable energy provider of the future. We think that’s great, we want to support it and this is why we will found a subsidiary in cooperation with technology partners to build the first large-scale plant there, which is meant to cascade into a string of several plants.

I think realising these two large projects in the years to come will attract other large partners that want to accompany us on our journey and make the whole thing really big.

Norway bets on gas and CCS to complement Europe’s energy transition

What’s the greatest financial hurdle for realising your projects? Is it the investment or operating costs?

At present, we’re negotiating projects that will be realised over several years and involve scaling up capacities. If you consider the entire lifetime of a project, the main problem are not the initial investment costs, but rather the operating costs. For example, operating costs account for around 70 percent of the total per litre of renewable fuel. Operating costs are dominated by the power price, which is why we need to either go to places where renewable electricity is cheap and abundant, or we create the policy conditions necessary to at least try out these things as demonstration projects – for example by dispensing with silly regulations. That would allow us to showcase this technology in our home territory. But in the future, further cost degression will depend on unlocking regions with low electricity costs.

In effect, we’re making e-fuels out of thin air

Where does the CO2 you use to make renewable fuels come from?

To make renewable fuels with this technology, we need renewable electricity, water and CO2. There is no good or bad CO2, it’s simply a molecule. We can use the CO2 resulting from making fertilisers, cement or from biogas plants, for example. You can remove it directly from the chimney or let it escape into the ambient air and remove it later, which has the same effect but is simply more expensive. But eventually, we will also be able to capture CO2 from the air – that’s expensive at present, but it will become affordable.

We want to use that CO2 removal technology soon in close cooperation with Swiss start-up Climeworks, which I consider one of our great assets in Europe because of their fantastic technology to remove carbon from the air. We have teamed up to realise a project to take practically all ingredients for sustainable fuel from the air. Using wind power, Climeworks removes CO2 from the air and, as a side effect, also captures water, which we can also use directly. So in effect, we’re making e-fuels out of thin air.

You may argue that this method of generating CO2 is quite costly, which is true, but the great advantage is that the process makes you geographically independent because you can do it anywhere. As a consequence, you can go to any location where renewable energy can be harvested in large amounts, even if there is no fertiliser plant nearby. You have to make an extra effort to get the CO2, but you get power cheaper. And because the power price has a much stronger influence on costs than CO2, it becomes worthwhile.

Many people haven’t understood yet that this is the reason why it makes sense to make this direct air capture technology really big right now and integrate it into the process. That’s also why we are strong advocates of this approach and are planning a joint project. Together, we can do something that makes economic sense and that you can do anywhere under the right circumstances. Even in Europe, there are many regions that could supply the continent with e-fuels.

Europe will not depend on the Sahara to get its renewable energy. We can do it in Norway, Portugal, Spain, Scotland and offshore. You can harvest so much wind and sun – if we’re flexible enough to go anywhere it is possible. Europe can become self-sufficient.

Which industries are particularly interested in using your products?

As I have mentioned, the steel industry wants to make clean steel. To do it, they need hydrogen and carbon monoxide, which they can get from us. Refineries also approach us because they need hydrogen today and would like to make it renewable instead of making it using methane – that’s only a small part of their process, but because they’re so large, that’s already quite a lot for us and good future business. Refineries have also started thinking about renewable fuels in more general terms, which means they not only need hydrogen but also hydrocarbons to substitute the crude.

Then we have the whole chemicals industry, which today uses everything that can be made with crude and natural gas as raw materials, either from refineries or they use them directly, for example to make basic raw materials for cosmetics, plastics and so on. Everybody who wants to make a renewable product must also look at the chemical plants that make the raw materials or at the refinery. Here again, we can be the ones supplying the raw materials.

To get more concrete: We will make a product that is comparable to crude in many respects, except it’s cleaner and renewable, in an installation comparable to the one we currently plan in Norway. This product will be available in two forms: One is liquid at ambient temperatures, which will go to a refinery to make fuels and other liquid products. The other has a wax-like consistency at room temperature and can be used to make paints, cosmetics, pharmaceuticals or car tyres, for example.

We have already been approached by a company from the cosmetics industry. We can refer them to our partner for the Norway project, a specialty refinery in Northern Germany. We supply the raw material to the refinery and the refinery then makes a processed primary product for cosmetics.

What’s Germany’s status when it comes to the hydrogen economy? There are many activities around the globe. Is the country still considered a pioneer?

Germany boasts some interesting companies in this sector. They’re still quite small, but there is potential to lead the way. But I tend to think in European rather than German terms and I believe we are in a position to build up an industry that could really carry this technology into the whole world. But we have to make sure we don’t destroy it with inappropriate policies, because then we could see a repeat of what happened to the solar and the wind industry: Huge first steps and efforts in Europe, then a sudden collapse and an industry transfer to the Far East. That would be a great pity. I hope policy is attentive enough to make sure that Europe remains an economic powerhouse in this sector – even if it’s not easy to develop a coherent policy for Europe because every member country has different interests: France has its nuclear power, Great Britain its gas power plants and Germany its coal plants. I don't envy the politicians.